Produk

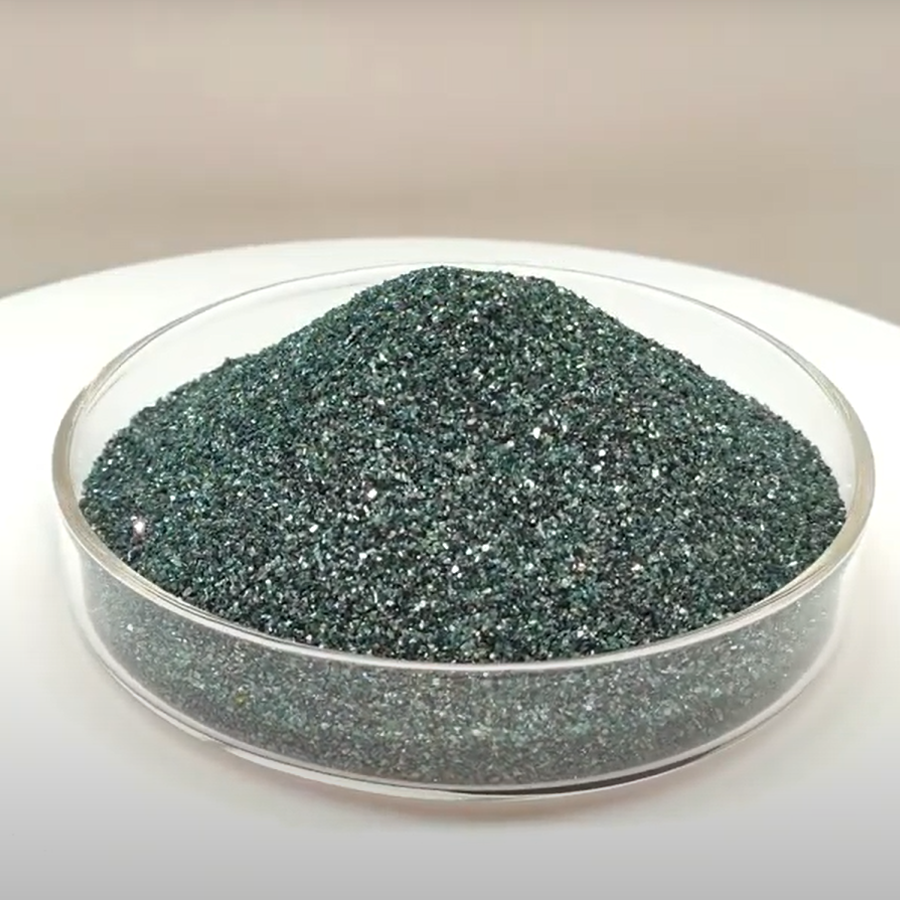

F12-F220 grit silikon karbida ijo

Green Silicon Carbide diprodhuksi dening panas wedhi silika lan sumber karbon, biasane petroleum coke, kanggo suhu dhuwur ing furnace.Asil saka proses suhu dhuwur iki tatanan kristal saka Silicon Carbide biji.Kualitas dhuwur, banyu diklasifikasikaké bubuk silikon karbida diklasifikasikake miturut standar sing tepat.

Wêdakakêna silikon karbida ijo minangka bahan abrasif sing atos kanthi distribusi ukuran partikel seragam.Kekerasan kasebut mung sawise berlian lan B4C, lan luwih angel tinimbang karbida silikon ireng.Dadi cocok kanggo nggiling macem-macem bahan hard kayata titanium alloy, marmer, carbide alloy, kaca tingal optik, keramik, etc.

Ing sisih liya, karbida silikon ijo duwe fitur sing luar biasa kayata stabilitas kimia sing dhuwur, tingkat ekspansi termal sing sithik, cocog kanggo lapisan tahan panas & tahan karat, cat, lan produk konstruksi liyane.

Fitur

1. Kapadhetan dhuwur

2. expansion termal kurang, resistance oksidasi dhuwur

3. resistance kimia banget

4. resistance kejut termal dhuwur

5. nyandhang dhuwur lan resistance atose

6. kekuatan dhuwur, resistance suhu dhuwur

7. kekuatan suhu dhuwur

Kimia Green Silicon Carbide lan Kapadhetan Bulk

| Analisis Kimia | Kapadhetan Massal: LPD = Kapadhetan Paket Loose | ||||||

| Grit No. | Min.%SiC | Maks.% C | Maks.%SiO2 | Maks.%Si | Maks.%MI | Min. | Maks. |

| 8# | 99.00 | 0.40 | 0.40 | 0.50 | 0.0200 | 1.35 | 1.43 |

| 10# | 99.00 | 0.40 | 0.40 | 0.50 | 0.0200 | 1.35 | 1.44 |

| 12# | 99.00 | 0.40 | 0.40 | 0.50 | 0.0200 | 1.41 | 1.49 |

| 14# | 99.00 | 0.40 | 0.40 | 0.50 | 0.0200 | 1.42 | 1.50 |

| 16# | 99.00 | 0.40 | 0.40 | 0.50 | 0.0200 | 1.43 | 1.51 |

| 20# | 99.00 | 0.40 | 0.40 | 0.50 | 0.0200 | 1.44 | 1.52 |

| 22# | 99.00 | 0.40 | 0.40 | 0.50 | 0.0200 | 1.44 | 1.52 |

| 24# | 99.00 | 0.40 | 0.40 | 0.50 | 0.0200 | 1.45 | 1.53 |

| 30# | 99.00 | 0.40 | 0.40 | 0.50 | 0.0200 | 1.45 | 1.53 |

| 36# | 99.00 | 0.40 | 0.40 | 0.50 | 0.0200 | 1.46 | 1.54 |

| 40# | 99.00 | 0.40 | 0.40 | 0.50 | 0.0200 | 1.47 | 1.55 |

| 46# | 99.00 | 0.40 | 0.40 | 0.50 | 0.0200 | 1.47 | 1.55 |

| 54# | 99.00 | 0.40 | 0.40 | 0.50 | 0.0200 | 1.46 | 1.54 |

| 60# | 99.00 | 0.40 | 0.40 | 0.50 | 0.0200 | 1.46 | 1.54 |

| 70# | 99.00 | 0.40 | 0.40 | 0.50 | 0.0200 | 1.45 | 1.53 |

| 80# | 99.00 | 0.40 | 0.40 | 0.50 | 0.0200 | 1.44 | 1.52 |

| 90# | 99.00 | 0.40 | 0.40 | 0.50 | 0.0200 | 1.44 | 1.51 |

| 100# | 99.00 | 0.40 | 0.40 | 0.50 | 0.0200 | 1.42 | 1.50 |

| 120# | 99.00 | 0.40 | 0.40 | 0.50 | 0.0200 | 1.40 | 1.48 |

| 150# | 99.00 | 0.40 | 0.40 | 0.50 | 0.0200 | 1.38 | 1.46 |

| 180# | 99.00 | 0.40 | 0.40 | 0.50 | 0.0200 | 1.38 | 1.46 |

| 220# | 99.00 | 0.40 | 0.40 | 0.50 | 0.0200 | 1.36 | 1.44 |

Green Silicon Carbide Grit Ukuran

| Kelas sandblasting | 8#10#12#14#16#20#22#24#30#36#40#46#54#60#70#80#90#100#120#150#180#220# |

| Kelas polishing | F230 F240 F280 F320 F360 F400 F500 F600 F800 F1000 F1200 F1500 F2000 |

| 240#280#320#360#400#500#600#700#800#1000#1200#1500#2000#2500#3000#4000#6000#8000# | |

| Cathetan: kita uga bisa disesuaikan miturut syarat pelanggan. | |

1.Blasting, lumahing Perawatan kanggo kaca, keramik, etc.

2. Produk Keramik.

3.Bahan mentah saka GC grinding wheel, sandpaper, kain abrasive cocok kanggo marmer lan granit.

4. Grinding hard alloy, non-ferrous logam, plastik, etc.

5.Bahan baku saka Whetstone, oilstone, grinding watu, watu abrasive lan ing.

Pitakonan Panjenengan

Yen sampeyan duwe pitakonan, please aran gratis kanggo hubungi kita.