Produk

Karbida Silikon Ijo Berkualitas Tinggi kanggo Polishing lan Grinding

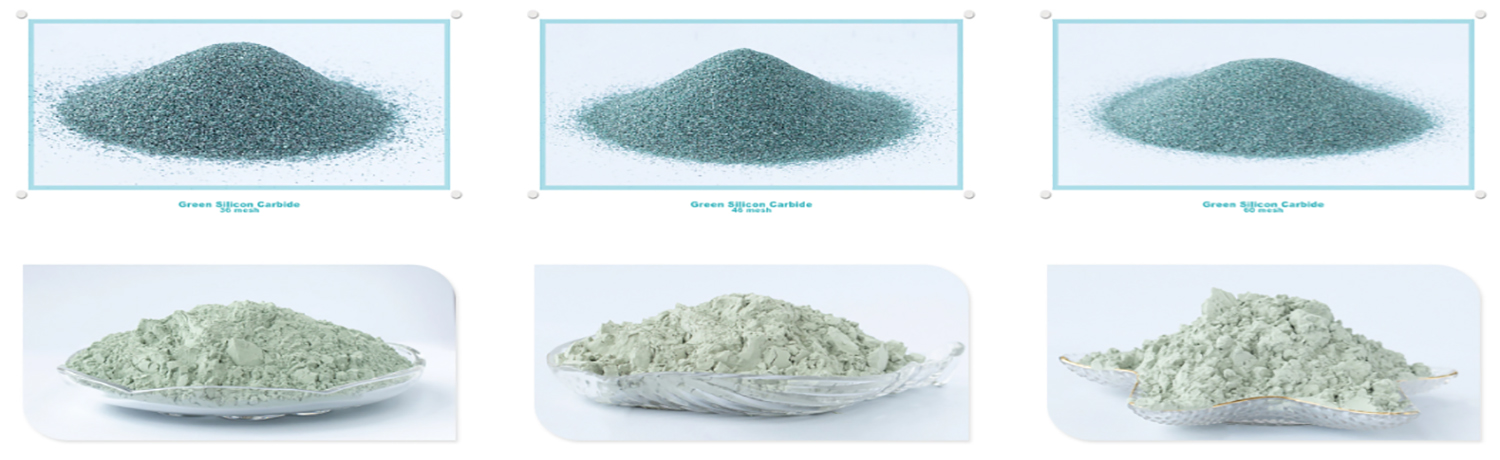

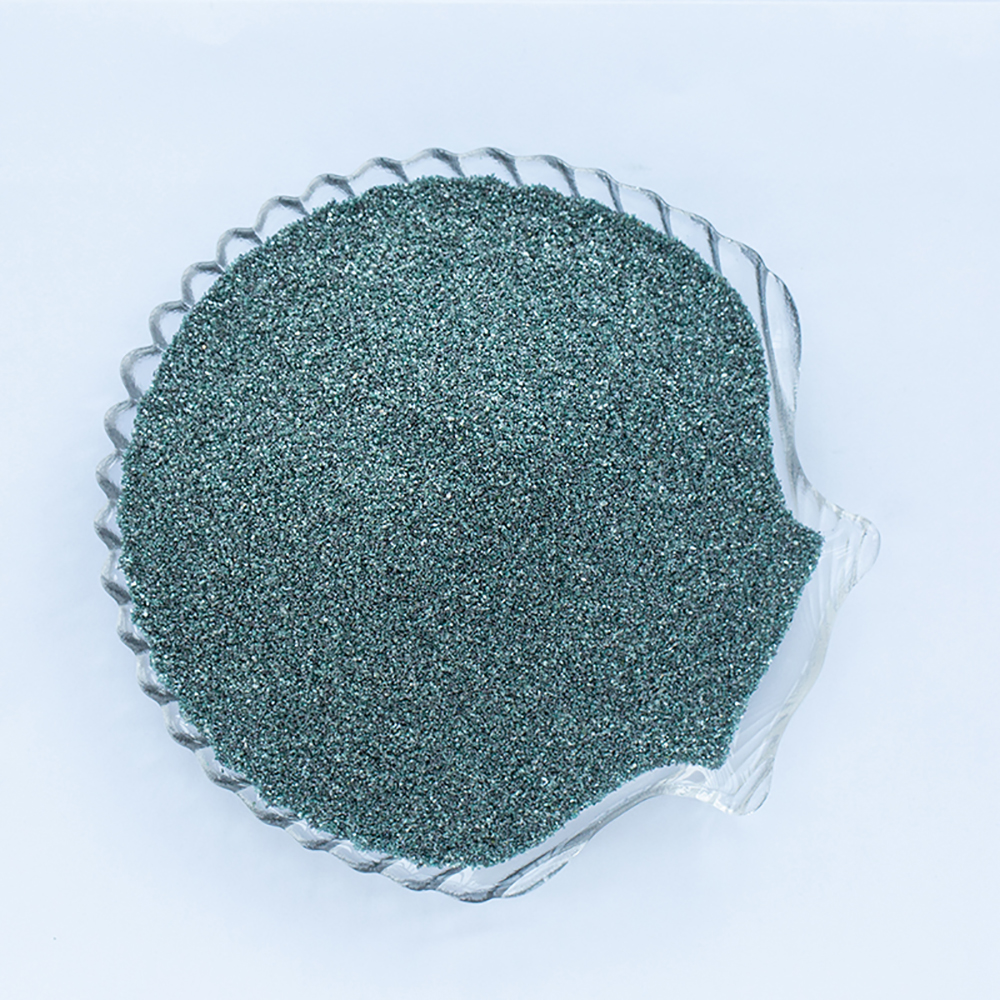

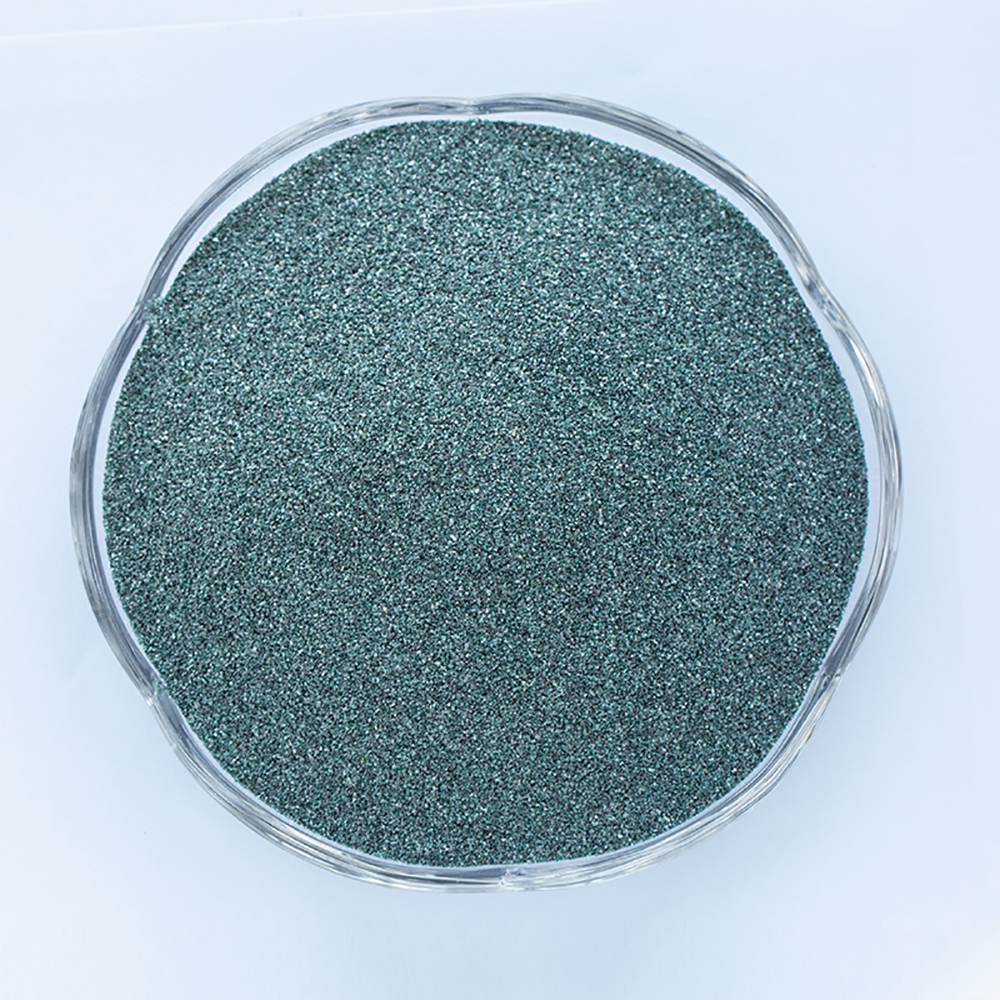

Deskripsi Green Silicon Carbide

Karbida silikon ijo minangka bahan abrasif berkualitas tinggi sing digawe saka biji silikon karbida lan coke petroleum ing tungku tahan listrik ing suhu dhuwur.

Green Silicon Carbide Grit Ukuran

| Kelas sandblasting | 8#10#12#14#16#20#22#24#30#36#40#46#54#60#70#80#90#100#120#150#180#220# |

| Kelas polishing | F230 F240 F280 F320 F360 F400 F500 F600 F800 F1000 F1200 F1500 F2000 |

| 240#280#320#360#400#500#600#700#800#1000#1200#1500#2000#2500#3000#4000#6000#8000# | |

| Cathetan: kita uga bisa disesuaikan miturut syarat pelanggan. | |

Kimia Green Silicon Carbide lan Kapadhetan Bulk

| Analisis Kimia | Kapadhetan Massal: LPD = Kapadhetan Paket Loose | ||||||

| Grit No. | Min. %SiC | Maks. % C | Maks. %SiO2 | Maks. %Si | Maks. %MI | Min. | Maks. |

| 8# | 99.00 | 0.40 | 0.40 | 0.50 | 0.0200 | 1.35 | 1.43 |

| 10# | 99.00 | 0.40 | 0.40 | 0.50 | 0.0200 | 1.35 | 1.44 |

| 12# | 99.00 | 0.40 | 0.40 | 0.50 | 0.0200 | 1.41 | 1.49 |

| 14# | 99.00 | 0.40 | 0.40 | 0.50 | 0.0200 | 1.42 | 1.50 |

| 16# | 99.00 | 0.40 | 0.40 | 0.50 | 0.0200 | 1.43 | 1.51 |

| 20# | 99.00 | 0.40 | 0.40 | 0.50 | 0.0200 | 1.44 | 1.52 |

| 22# | 99.00 | 0.40 | 0.40 | 0.50 | 0.0200 | 1.44 | 1.52 |

| 24# | 99.00 | 0.40 | 0.40 | 0.50 | 0.0200 | 1.45 | 1.53 |

| 30# | 99.00 | 0.40 | 0.40 | 0.50 | 0.0200 | 1.45 | 1.53 |

| 36# | 99.00 | 0.40 | 0.40 | 0.50 | 0.0200 | 1.46 | 1.54 |

| 40# | 99.00 | 0.40 | 0.40 | 0.50 | 0.0200 | 1.47 | 1.55 |

| 46# | 99.00 | 0.40 | 0.40 | 0.50 | 0.0200 | 1.47 | 1.55 |

| 54# | 99.00 | 0.40 | 0.40 | 0.50 | 0.0200 | 1.46 | 1.54 |

| 60# | 99.00 | 0.40 | 0.40 | 0.50 | 0.0200 | 1.46 | 1.54 |

| 70# | 99.00 | 0.40 | 0.40 | 0.50 | 0.0200 | 1.45 | 1.53 |

| 80# | 99.00 | 0.40 | 0.40 | 0.50 | 0.0200 | 1.44 | 1.52 |

| 90# | 99.00 | 0.40 | 0.40 | 0.50 | 0.0200 | 1.44 | 1.51 |

| 100# | 99.00 | 0.40 | 0.40 | 0.50 | 0.0200 | 1.42 | 1.50 |

| 120# | 99.00 | 0.40 | 0.40 | 0.50 | 0.0200 | 1.40 | 1.48 |

| 150# | 99.00 | 0.40 | 0.40 | 0.50 | 0.0200 | 1.38 | 1.46 |

| 180# | 99.00 | 0.40 | 0.40 | 0.50 | 0.0200 | 1.38 | 1.46 |

| 220# | 99.00 | 0.40 | 0.40 | 0.50 | 0.0200 | 1.36 | 1.44 |

1.Abrasive: Green silicon carbide digunakake digunakake minangka bahan abrasive ing macem-macem industri, kalebu otomotif, aerospace, metalworking, lan perhiasan.

2.Refractory: tungku lan kiln amarga konduktivitas termal dhuwur lan expansion termal kurang.

3.Electronics: LED, piranti daya, lan piranti gelombang mikro

4. Energi surya: panel surya.

5. Metalurgi

6. Keramik: alat nglereni, bagean tahan nyandhang, lan komponen suhu dhuwur

Pitakonan Panjenengan

Yen sampeyan duwe pitakonan, please aran gratis kanggo hubungi kita.

wangun pitakonan

Tulis pesen sampeyan ing kene lan kirimake menyang kita